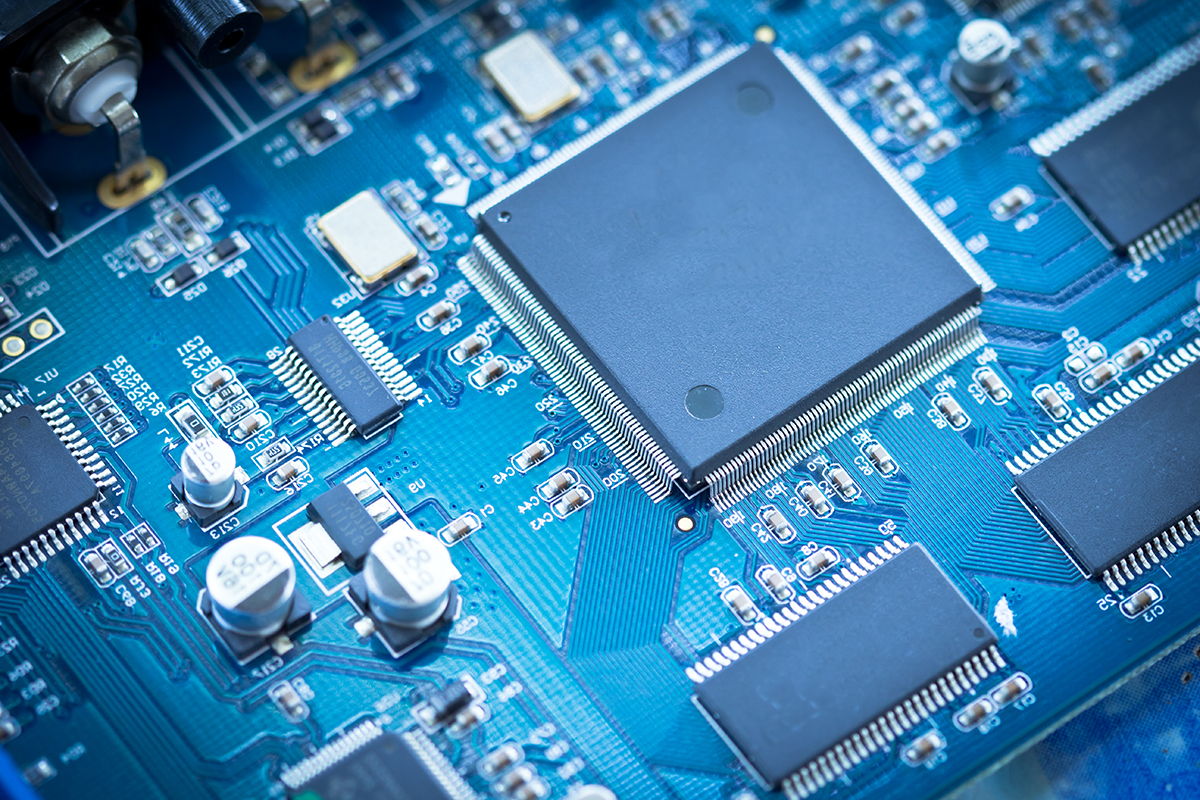

Electronic materials

Introduction of industry

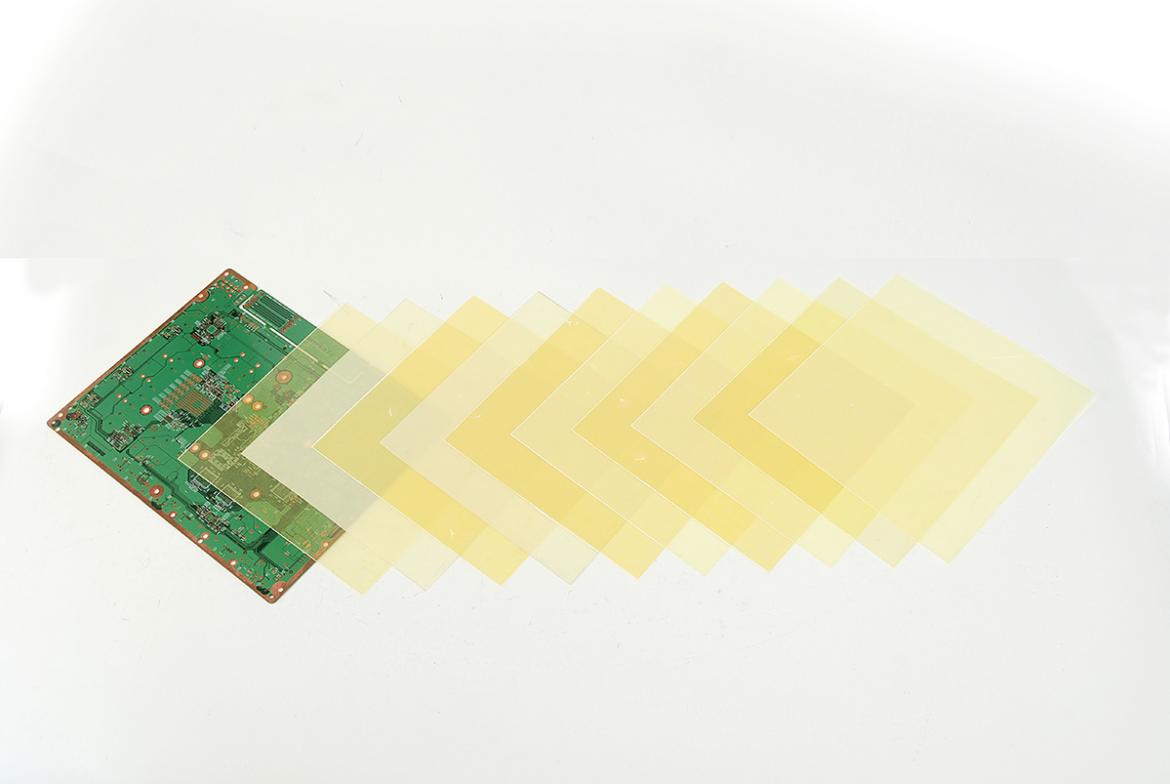

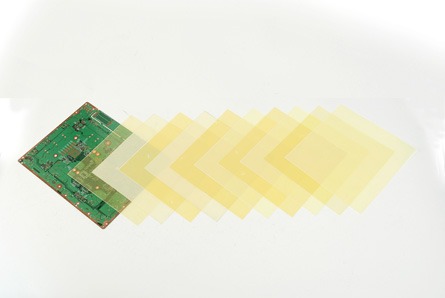

Phenolic resin can be applied in copper-clad laminates industry, especially in FR4, FR5 and CEM-1. The major purpose of phenolic resin is the hardener for epoxy resins. The resins can improve the properties of Tg point, thermal stability, coefficient of thermal expansion, and low water-solubility for CCL. KBC products can be classified into liquid and solid type, and widely applied in halogen free and lead free process procedure.

Application: copper-clad laminates, FR4, FR5, CEM-1, BPA Novolac, halogen free, lead free.

Products introduction

Block and flack type phenolic resin

| Product No | Appearance | Type | Softening Point (°C) | Application |

| KBT-520F | Light reddish solid | N-PN | 110-120 | Epoxy hardener |

| KBT-610F | lLight brownish solid | BZ | 67-73 | Epoxy hardener |

| KBT-3122F | Dark black solid | TPN | 122-138 | UV block |

| KBT-3192F | Light yellowish solid | PN | 99-105 | Epoxy hardener |

| KBT-6614F | Light brownish solid | BN | 112-128 | Epoxy hardener |

| KBT-6620F | Light brownish solid | BN | 102-118 | Epoxy hardener |

Liquid type phenolic resin

| Product No | Appearance | Type | Solid Content (°C) | Viscosity (cps/25°C) | Application |

| KBT-610D60 | Yellowish liquid | BZ | 59-61 | 70-110 | Epoxy hardener |

| KBT-3192M65 | Yellowish liquid | PN | 64-66 | 2500-3500 | Epoxy hardener |

| KBT-6615MP65 | Light brownish liquid | BN | 64-66 | 7500-9500 | Epoxy hardener |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Share social media