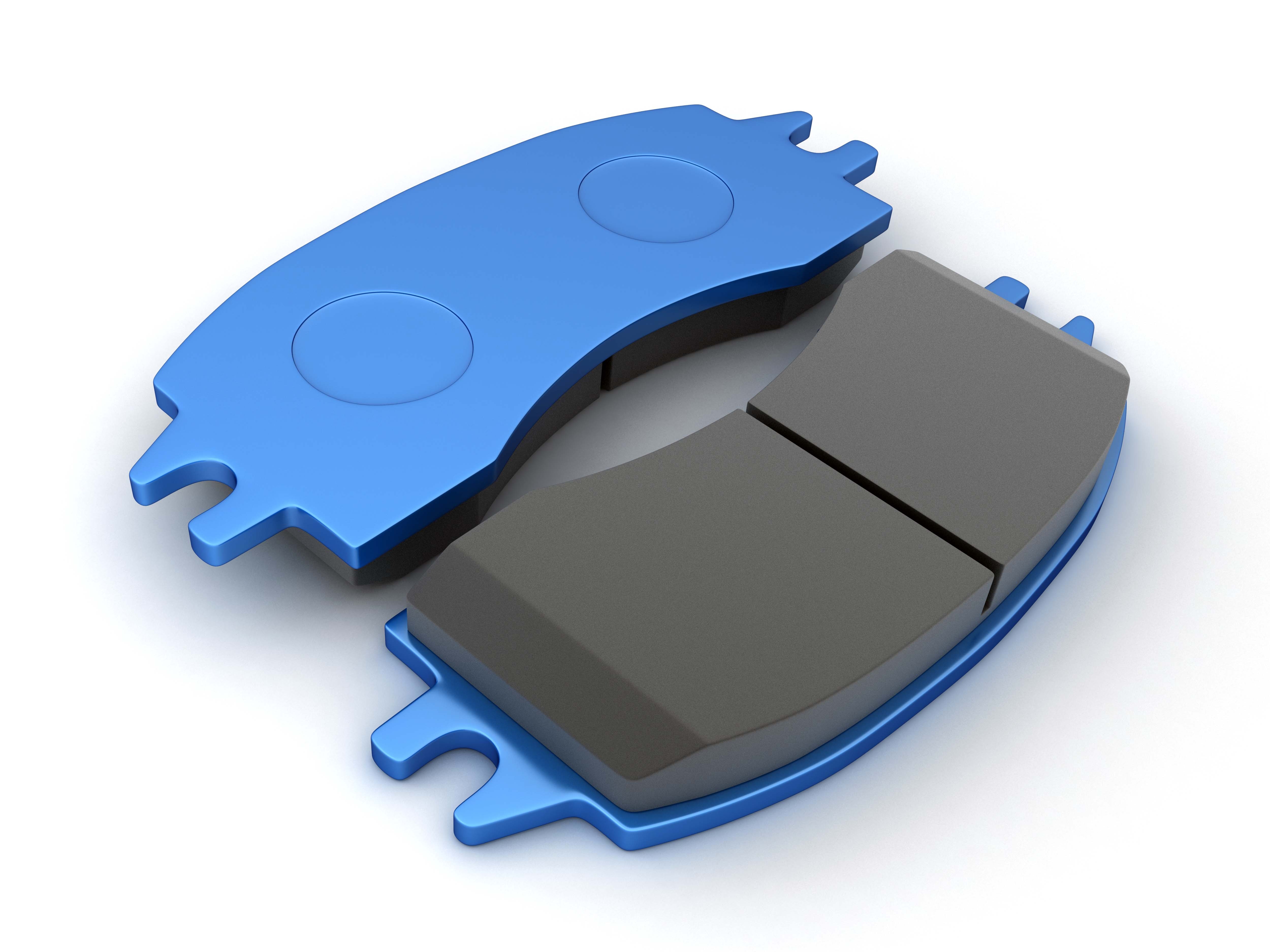

Brake lining, Brake Pad, Clutch facing

Introdution of industry

Friction materials were usually composed of phenolic resin, asbestos /NAO fiber, metal fiber, mineral fiber and inorganic filler etc. At the rapid changes in technology, more and more advanced materials have been applied in this field. KBC cooperates with a Japan company to develop new era of phenolic resin for high performance of binders for OEM and aftermarket customer.

Application: brake pad, brake linings, clutch facing, motorcycle, bike, wheels, brake for construction machinery, brake for equipment.

Products introduction

Products introduction

Powder type phenolic resin

Product No | Resin type (Modification) | Gel Time (Sec. /150 ◦C) | Flow (mm /125 ◦C) | Hexamine (%) | Description | Application |

KBT-3540 | Straight | 50 - 80 | 30 - 50 | 9 | Moldability | DP, BL |

KBT-3610 | Straight | 50 - 80 | 20 - 40 | 9 | Moldability | DP, BL |

| KBT-3640 | Straight | 55 - 85 | 18 - 38 | 9 | High Molecular, Moldability | DP, BL |

| KBT-3648 | Straight | 50 - 80 | 22 - 42 | 7 | High Molecular, Moldability | BL |

| KBT-3853 | Epoxy | 50 - 80 | 30 - 50 | 11 | Water resistance | BL, Adhesive |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor